Prime Scientific - Viscosity of Peanut Butter Cream

We tested generic peanut butter samples for their viscous properties and in this blog, we share our insights.

i.

ViscoQC 100 Rotational

Viscometer

ii.

RH6 spindle

iii. 600 ml graduated glass beaker

i.

Amount of the sample was

taken that can fill the beaker up to the 500 ml graduation. Care was taken not

to disturb the sample structure while scooping to ensure the sample layers are

uniformly stacked such as not to create any air gaps.

ii.

The RH6 spindle was

inserted into the beaker and the apparatus centered under the viscometer. The

spindle was attached to the viscometer via the magnet coupling and the

instrument confirmed the spindle was inserted by a bleeping sound after which

the spindle data is displayed on the screen.

iii. The sample was tested at different speeds starting at low speeds and then moving up to high speeds. The viscosity reading was taken after 60 sec in each speed

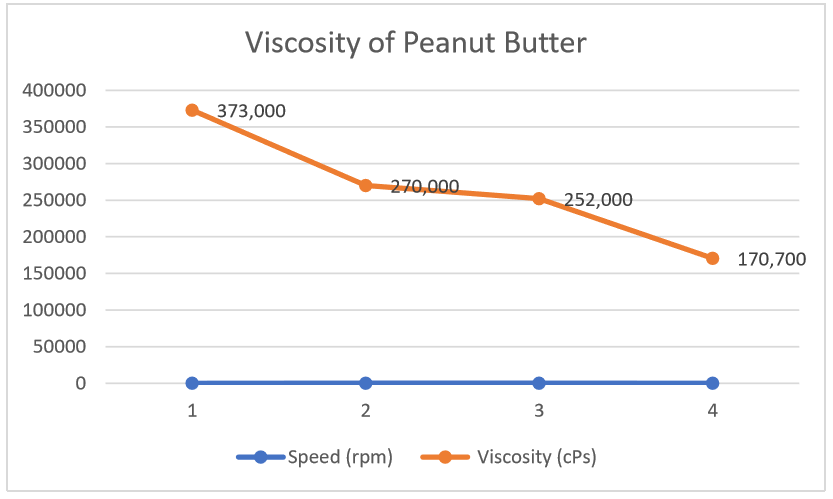

The results obtained are shown in below Table 1, and Chart 1:

Table

1: Results table for viscosity test of peanut butter

|

Speed (rpm) |

Viscosity (cPs) |

Torque% |

|

0.3 |

373,000 |

11.20% |

|

0.6 |

270,000 |

16.20% |

|

2 |

252,000 |

50.40% |

|

4 |

170,700 |

68.30% |

Chart 1: Viscosity vs. Rotational Speed Graph

i.

Peanut butter, as assumed,

displays shear thinning behavior. When the speed in rpm was increased, the

butter viscosity decreased. This corresponds to the case where a consumer will

apply spreading force on a peanut butter to make it an a bread, therefore, the

decrease in viscosity will allow it to be spreadable.

ii.

The measurement range

obtained was 170,000 to 373,000 according to the speed.

iii.

At 50% approx. torque, the

viscosity obtained was 252,000 cPs in a speed of 2 rpm.

iv.

When the speeds were

continued until 12 rpm, the viscometer showed an out of range torque% (above

90%). In order to measure in further speeds, a higher range spindle like RH7

can be used. However, it is not advisable to go for high speed with this type

of samples because the structure will be sheared extensively and will not

recover as shown below.

v.

When speed of 12 rpm was

reached, a measurement was done to a lower speed of 2 rpm and it was found that

the viscosity dropped much lower than the original value of 252,000 cPs at the

same speed. This indicated that the structure of the sample was disturbed and

did not recover its viscous properties.

Prime Scientific

Prime Scientific provides equipment, instruments and other related products and materials. We aim to be a one stop shop for all our customers laboratory needs. Since 2001, Prime has strived to provide the best services and solutions to the scientific community in the region.