Prime Scientific - New Dimensions in Viscometry

By Ziryab Imad Ali Ahmed on May 26, 2018

IntermediateBut what are its features?

ViscoQC™ 100 automatically detects spindles and guards (Toolmaster™, TruGuard), eliminating the possibility of errors which occur when manually choosing the spindle. To make the setup even more convenient, the spindles have a magnetic coupling which allows quick one-hand mounting/ dismounting and protects the spindles against bending. The viscometer checks its proper alignment using an intuitive integrated digital leveling function at startup, before and during measurements, so you can always be sure that the instrument is leveled, without needing to check it manually. The result: Excellent reproducibility of your measurements.

Those are quite differences from the standard B-Type viscometer we were used to in the market.

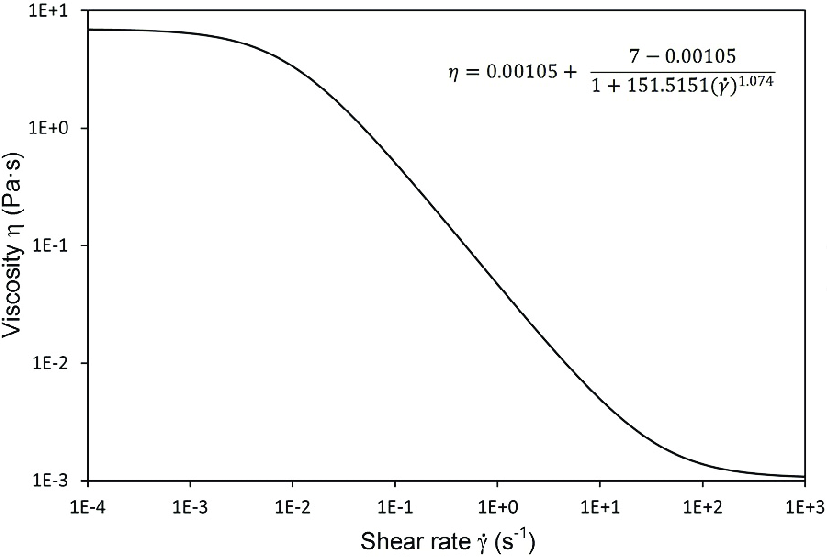

Moving on to application, there are many different applications for this instrument. However, bear in mind that this instrument does not aim to create a flow curve diagram, but it measures the viscosity at a specific point in the flow curve

As you can see from the above diagram, this is a typical flow curve generated from plotting the viscosity at different shear rates. It is apparent from this flow curve that the type of material is dilatant, in that its viscosity decreases with increase in shear rate.

The shear rate is correlated to the speed of the measuring system used. In case of the rotational viscometer, the speed remains constant during the measurement. Each measurement ends with one viscosity reading corresponding to one speed, in other words, a specific shear rate.

But how is this useful?

In applications of quality control where the experimenter is interested in only one value, the rheometer type viscotesters which can plot flow curves become quite expensive, especially owing the cost of the high-end instrument and its accessories and data evaluation software.

For simple applications such as quality control of gums for example, the exact value on a set speed is usually required to determine the quality of the gum used.

For that type of test, the sample is simply filled onto a 600 ml beaker up to the mark and is presented to the viscometer. A specific speed is set usually ranging from 100 to 150 rpm and the values noted.

It should be noted that the best speed to get an accurate vaue is the speed at which maximum torque % is reached. If the value is between 80% to 100%, according to the norms, it should be sufficient to give a confident value of the viscosity.

According to standard procedures of gums measurements, it has been found that the above mentioned speed range is the speed that obtains the most acceptable viscosity readings.

In summary, it can be said that the viscosity of different material can be tested at a single shear rate point using a rotational viscometer. The

ViscoQC™ 100 is not only able to acheive that, but it gives that extra mile of easing the operation of the experimenter, and aiding in reproducing the best results again and again.

For more information on the ViscoQC™ 100, click on here to read more about the product.

There is an interesting application note also available here, for more complex applications according to the DIN standards that can be achieved by the ViscoQC™ 100

Was this article helpful?

More articles on Application Knowledge