Crude Oils and Fuels Testing

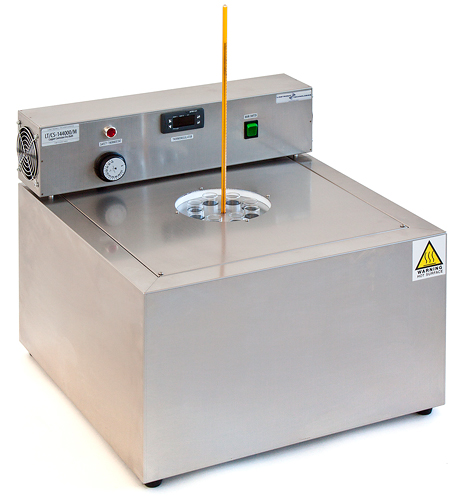

Linetronics COPPER CORROSION DRY BATH ASTM D 130

Linetronics COPPER CORROSION DRY BATH ASTM D 130

Fully made in stainless steel Dry Bath suitable for the accommodation of up to 8 glass test tube D130 Thermostated by a digital thermoregulator PID that controls a temperature range from ambient to 180°C Over-temperature device with alarm and probe PT100A Power supply: 230 Vac 50 Hz or 115 Vac to be specified in PO CE Marked

Switzerland

Automatic horizontal REID Vapour pressure ASTM D323-B & ASTM D4953

9cae87.jpg)

Automatic horizontal REID Vapour pressure ASTM D323-B & ASTM D4953

Bath made in stainless steel suitable for the accommodation of up to two (2) vapour pressure cylinders according to ASTM specifications

Bath temperature range from ambient to +80 °C ±0.1°, filling level 20 liters.

Motorized stirrer with shaft, drain tap.

Electric immersion Heather controlled by PID system

Drive system for swing gently the vessel till 350° right/left

2 x Connection heads LT/RC-179000-D included for coupling with the vapour cylinder

Secure handle cover for open bath

Bath equipped with a Touch screen panel PC o TFT/LCD 8” o 40 Gb HD o Resolution 1024x768 and 16M colours o 2 x USB Ports for connecting pen drive and printer

The dedicated software manages: o The bath temperatures by means of a PT100 sensor class A that can be displayed in °C / °F, including the over temperature safety alarm

2 (two) electronic sensors pressure transducers / electronic pressure gauges supplied for the coupling to the test vessels

Cables and connectors

Dedicated software for real time monitoring and recording that includes: o Display of the pressure in bar / psi / Kpa o Graph creation in real time during the test o Invalid test indication o Export of files in xls. / .pdf / jpg. format o Calibration up to 100 points

Power supply: 220Vac 50/60Hz

Automatic Reference fuel blending unit for determination of Octane Number, and Cetane Number

Automatic Reference fuel blending unit for determination of Octane Number, and Cetane Number ASTM D613, ASTM D2699, ASTM D2700, and ASTM D2885

Instrument composed by:

Floor instrument compact and solid structure painted with antiepoxy products, include the refrigerator system (with Gas CFC free) and dedicated electronic boards.

Linetronic fixing system for glassware that allow an easy cleaning of all components

Safety systems: Overheating alarm and protection, over-pressure protection system, sample bottle wrong position protection, Standby module for energy saving.

Cooling Performance: able to grant working temperatures of -20°C …

Up to 6 liquid tank connection facility

Integrated balance assure an accuracy of +/- 0.01 ON/CN (0.2%)

Linetronic Management software running on 8” High-brightness TFT with resolution 1024x768: o Pre-setting for methods : ▪ ASTM D2699 / D2700 / D2885 / D613 o Customizable blending parameters o Settable bath temperature and controlled by PT100 A

OilLab 611 - Aniline Point

OilLab 611 - Aniline Point

ASTM D611-E

IP 2-E

Correlated to

ASTM D611-A, B, C, D

IP 2-A, B, C, D

- Automatic unit able to measure products with ASTM color less than 8

- Automatic movement of the head up and down

- Electric heather controlled by PID system and on-board cooling system with liquid peltier exchanger grant the following temperature: -10…+160°C

- Heating /cooling dry bath for more safety

- Removable glass cell for cleaning

- Not aniline is touched by the operator: a small hole on the head support is used for the introduction of the aniline by syringe with luer lock (10 ml) when the glass cell with sample is already installed

- Wide 8" touch panel pc is installed with dedicated managing software Aniline programs as for standard heating and cooling profile and costums procedure available

- Temperature probe fiber optic and mirror are inside the sample and not outside the glassware

- Automatic stirrer made of brass, 3 coils

- Solid structure painted with anti-acid epoxy products

- Double detection system able to detect dark and clear samples

- Managed by a touch screen panel PC:

- TFT/LCD 8”

- 40 Gb HD

- resolution 1024 × 768 and 16 M colours

- 2 × USB Ports for connecting pen drive and printer

- The dedicated software manages:

- the bath temperatures by means of a PT100 sensor class A that can be displayed in °C / °F, including the over temperature safety alarm

- Dedicated software for real time monitoring and recording that includes:

- graph creation in real time during the test

- invalid test indication

- export of files in xls / pdf / jpg format

- calibration up to 100 points

Power supply

- 220 Vac 50/60 Hz

- 115 Vac 50/60 Hz

Dimensions

- 53 × 31 × 75 cm

WATER IN CRUDE OIL/DEAN AND STARK ASTM D4006, Linetronics, Switzerland

WATER IN CRUDE OIL/DEAN AND STARK ASTM D4006, Linetronics, Switzerland

5 x Heating mantle 500 Watt with steel rod and clamp

5 x 1000 ml round bottom flask 24/40

5 x Liebig Condenser 24/40

5 x Drain tube

5 x Graduated 10 ml receiver type E

Power supply: 230 Vac 50 Hz or 115 Vac to be specified in PO

CE Marked