Lubricants and Greases Testing

Penetrometer: PNR 12

PNR 12 automatically measures the resistance a material provides to being pierced by a specifically shaped test body. The harder the test material, the more pointed and needle-like the test body should be.

The penetrometer is used for consistency and plasticity determination of pasty, creamy, semi-solid or highly viscous samples.

ASTM D5

ASTM D1403

ASTM D217

ASTM D7342

ASTM D943

ASTM D1321

Linetronics Semi-automatic Apparatus for Grease Separation - one place

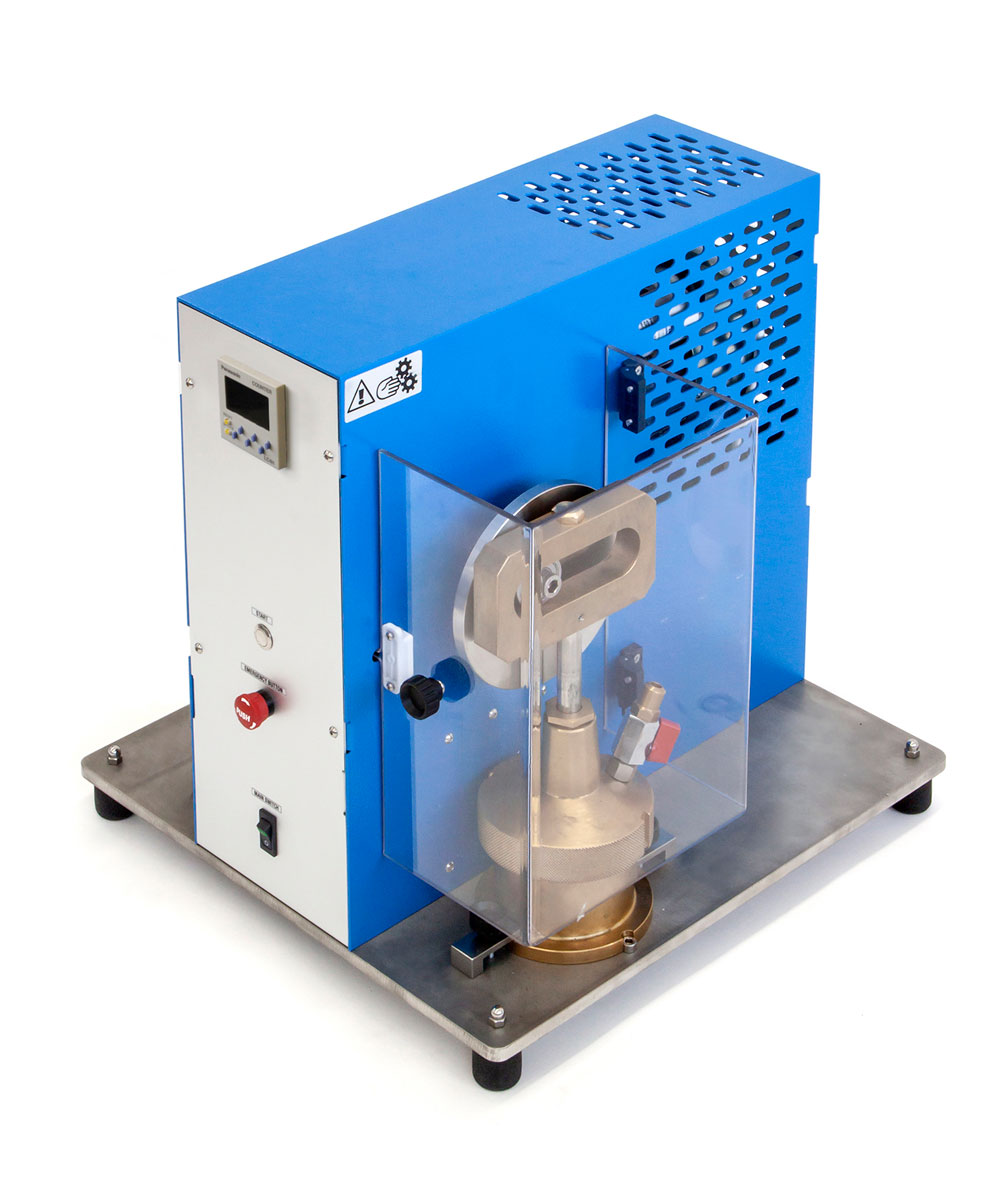

Item Code: LT/GW-70000-1/M

Linetronics Semi-automatic Apparatus for Grease Separation - one place

Instrument composed by:

Metallic case structure painted with anti-acid products to manipulating fats automatically

1 x greases manipulator with: o Brass body (grease cup) o Brass cover with screw connection and air valve/thermometer holder o Stainless steel piston with ground-slideway brass handle allowing connection to slave unit or automatic worker o Disc complying with ASTM D217 with 51 holes of 6.35mm

Control panel equipped with start/stop button, Emergency stop, 5 figure stroke counter and automatic preselector

Security cover made in PMMA with emergency stop sensor

Power supply 220 or 115 Vac (to be specified in PO)

Dimensions: 43x45x46 cm – Gross weight 47 Kg

User manual and power cable making part of scope of supply

Made by Linetronics, Switzerland

Automatic CLOUD & POUR POINT

Automatic CLOUD & POUR POINT

Instrument composed by:

Bench top instrument compact and solid structure painted with anti-

epoxy products, include the double stage motor-compressor refrigerator

system (with Gas CFC free) and dedicated electronic boards.

Analytical head made in aluminium and corrosion resistant plastics,

automatic up-middle-down movement with locking system.

Linetronic fixing system for glassware that allow an easy cleaning of all

components

Safety systems: Overheating alarm and protection, over-pressure

protection system, head wrong position protection, Stand-by module for

energy saving.

Cooling Performance: able to grant working temperatures of

-90°C ...+60°C

Linetronic Management software running on 12” High-brightness TFT

with resolution 1024x768:

o Pre-setting for methods:

▪ ASTM D2500 / IP 219 / ISO 3015 (CLOUD)

▪ ASTM D97 – D5853 / IP 15 / ISO 3016 (POUR)

o Customizable analysis parameters

o Settable bath temperature and controlled by PT100 A Class

with 0,1°C precision

o More than 60’000 analysis storage capacity

o 2 x USB for connecting: mouse, keyboard and software

updates

o 1 x RJ45 Ethernet / Lims connection

o Integrated beeper for end-test notification

Included: Glass cell with silver bottom, PT100 for sample temperature,

detection fiber optic, Pour detection sensors.

Weight: only 75 Kgs.

Footprint: Width 66 x Depth 66 x Height 80 cm

Power supply 220 or 115 Vac (to be specified in PO)